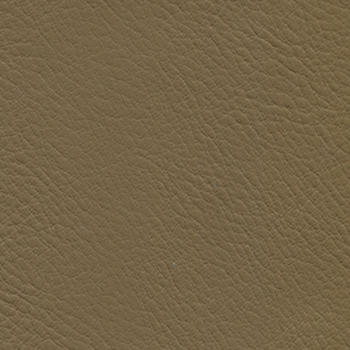

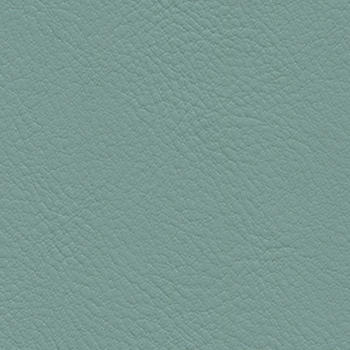

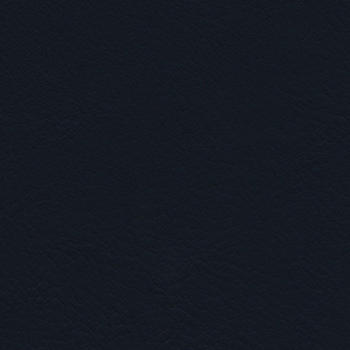

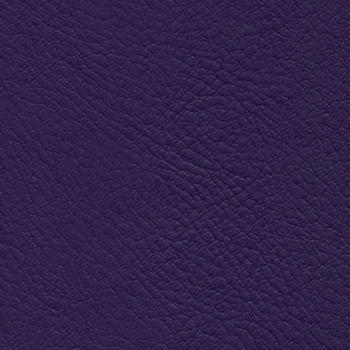

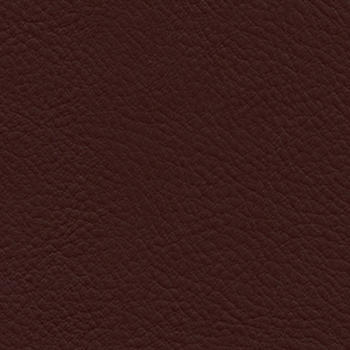

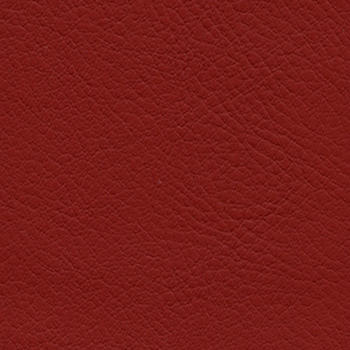

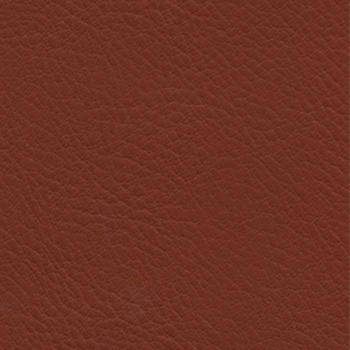

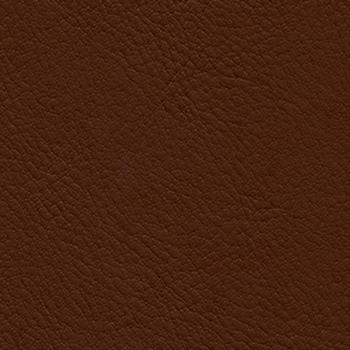

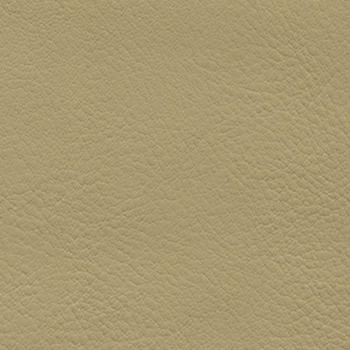

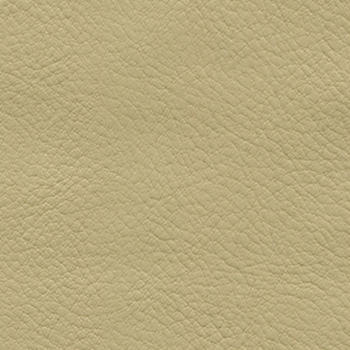

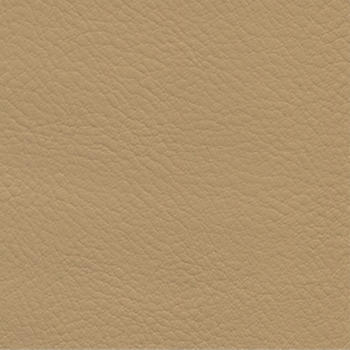

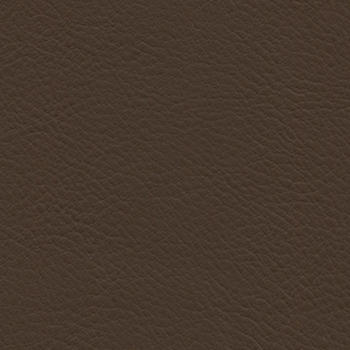

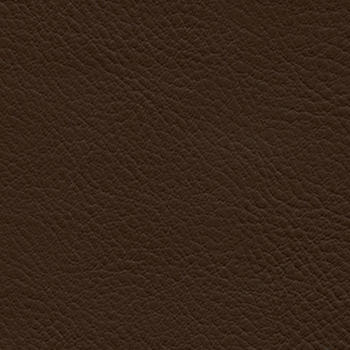

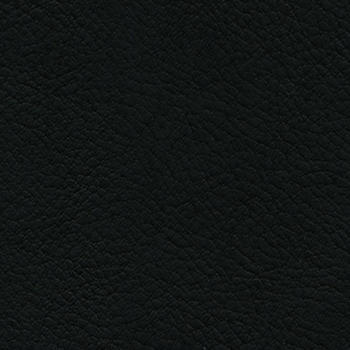

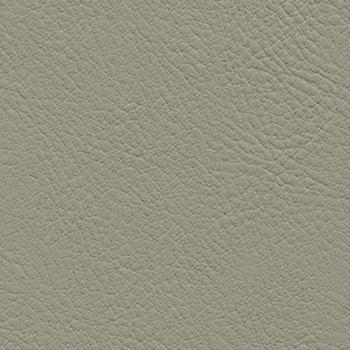

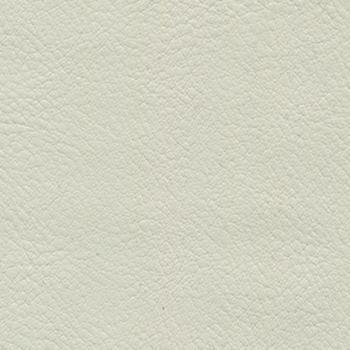

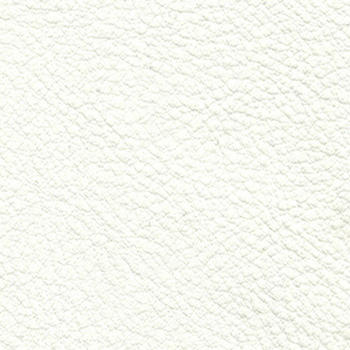

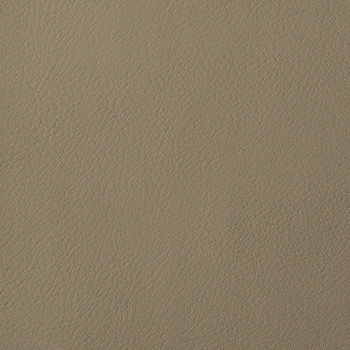

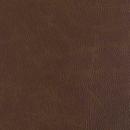

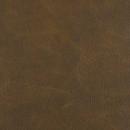

Available Colors

PVC Free Polyurethane

Bleach Cleanable

FR Free – Compliant with CAL AB 2998

PFAS Free

*

*ACT® Registered Certification Marks

Technical Details

| Fabric Specifications | |

| Face | 100% PVC Free Polyurethane |

| Backing | 100% Polyester |

| Bleach Cleanable | Yes Ratio: 90% Water / 10% Bleach Solution |

| Weight | 16.5 oz. per linear yd |

| Thickness | .85 mm |

| Width | 54" |

| Roll Size | 30 yards |

| Directional | No |

| Railroaded | No |

| Additional Attributes | |

| PFAS Free | Yes |

| PVC Free | Yes |

| Prop 65 Compliant | Yes |

| 16P Phthalate Free | Yes |

| Free of Added FR Chemicals / CAL AB2998 Compliant | Yes |

| Free of Added Anti-Bacterial Chemicals | Yes |

| Free of Added Anti-Microbial Chemicals | Yes |

| BPA Free | Yes |

| Free of Conflict Minerals | Yes |

| Formaldehyde Free | Yes |

| Free of Heavy Metals | Yes |

| Lead Free | Yes |

| Sulfide Stain Resistant | Yes |

| TRIS Free | Yes |

| Low VOC | Yes |

| Performance Characteristics | |

| Abrasion Resistance ASTM D4157 | 250,000 double rubs* |

| Tensile Strength CFFA-17 | Warp: 143.0 lbs. Fill: 105.0 lbs. |

| Tear Strength CFFA-16 | Warp: 7.4 lbs. Fill: 12.7 lbs. |

| Seam Slippage CFFA-14 | Warp: 55.9 lbs. Fill: 44.9 lbs. |

| Colorfastness to Crocking AATCC 8 | Dry: 5.0 Wet: 5.0 |

| UV Resistance CFFA-2 | 200 hours |

| Adhesion CFFA-3 | Warp: 10.3 lbs. Fill: 9.1 lbs. |

| Blocking CFFA-4 | 1 |

| Cold Crack CFFA-6 | -20° F |

| Flex CFFA-10 | 25,000 cycles |

| Hydrolysis | 5 Weeks |

| Flammability** | |

| CAL TB 117-2013 | Passes |

| NFPA 260 | Class 1 |

| UFAC | Class 1 |

| Recommended Cleaning | |

| Please refer to Detailed Cleaning Instructions. |

| Although we try hard to make sure colors on our site are accurate, actual colors may vary. Please order samples prior to making a purchase. | |

| The use of polyurethane for welt cord in upholstery applications is strongly discouraged. Even though Burch's polyurethane products are designed to exceed industry abrasion standards, when used with welt cord the exposed material becomes more vulnerable to abrasion and may experience premature de-lamination. Burch cannot be held responsible for damage that may occur when used in a welt cord application. | |

| Final determination of the suitability of this product for an application rests with the user. | |

| * Abrasion test results exceeding ACT Performance Guidelines are not an indicator of product lifespan. Multiple factors affect fabric durability and appearance retention. | |

| ** This term and any corresponding data refer to the typical performance in the specific tests indicated and should not be construed to imply the behavior of this or any other material under actual fire conditions. |